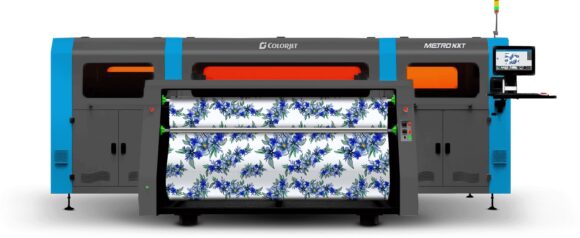

Description

FEATURES

INDUSTRIAL LEVEL PRINT HEADS Up to 8 staggered heads CMYK configuration with 5,7,12 pl variable ink drop technology attaining sharp quality with high production.

LEAF CLAMPS Polished steel clamps placed at either side to prevent paper edges from curling.

INK DEGASSING SYSTEM To remove bubbles and gastrapped in ink tubes and avoid ink starvation.

MULTIPLE BRUSH ROLLER To ensure effective wrinkle-free media feeding and take-up.

DANCING ROLLER To provide continuous uniform tension and roll alignment for media from feeding to take up.

LINEAR MOTOR Linear motor with high precision dual guide rail beam helps improve printing speed and ensure printing accuracy.

METAL ENCODER More precise ink jetting at high speeds, effectively leading to longer service life .

HSTR High Sense Paper Tension regulator. It detects fluctuation in tension and corrects it almost instantly.

To Prevent cockling of paper & provide precise ink absorption on the media.

ASTActive Seaming Technology for superior quality at high speed.

Z ENCODERFor precise head height adjustment when calibrating.

SPECIFICATION

SubliXpress Plus |

||||||||

|

Models

|

X4403

|

X8403

|

X4806

|

X8803

|

||||

| Printing Technology |

Drop-on-demand, Piezo Electric Inkjet

|

|||||||

| Type of Print head |

300dpi

|

300dpi

|

600dpi

|

300dpi

|

||||

| No. of Print Heads |

4

|

4

|

8

|

8

|

||||

| Print Heads | Type |

Industrial Grade Jetting Assemblies

|

||||||

| Resolution |

Upto 2400 dpi

|

|||||||

| Height Adjustment |

Upto 20mm

|

|||||||

| Cleaning Method |

Pressure Purge and Wiping

|

|||||||

| Wetting Control |

Piezoelectric actuations

|

|||||||

| Inks | Types |

Dye Sublimation Aqueous based Inks

|

||||||

| No. of Color |

4

|

8

|

4

|

8

|

||||

| Ink Colors |

CMYK

|

CMYK,Blue,Orange,

Fluoresent Yellow, Fluoresent Magenta |

CMYK

|

CMYK,Blue,Orange,

Fluoresent Yellow, Fluoresent Magenta |

||||

| Supply |

10 litre Refillable tank

|

|||||||

| Media | Max. Thickness |

Upto 20 mm

|

||||||

| Max/Printing Width |

Upto 1830 mm

|

|||||||

| Feed Roll Daimeter |

Upto 900 mm

|

|||||||

| Distance Accuracy |

Error of less than +0.3 % of distance travelled, or +0.3 mm, whichever is greater

|

|||||||

| Media Drying System |

Infrared Heaters

|

|||||||

| Printing Interface |

USB 3.1

|

|||||||

| Rip Software Supported |

Onyx(ColorJet Edition)

|

|||||||

| File Format |

JPEG/TIFF/BMP/PDF (RGB/CMYK)

|

|||||||

| Power Requirements(Print Engine) |

AC 220 V, 43 A, 50/60 Hz

|

|||||||

| Power Requirements(Dryer) |

AC 220 V, 20 A, 50/60 Hz

|

|||||||

| Dimensions (Printer Only) |

3926 x 1235 x 1824 mm

|

|||||||

| Feeder Dimension |

2415 x 1118 x 1050 mm

|

|||||||

| Dimensions (With Packing) |

4200 x 2260 x 2050 mm

|

|||||||

| Weight |

N.W 1650 K.G, G.W. 1850 Kg

|

|||||||

| Connected Load |

8 K.W

|

|||||||

| Operating Conditions | Temperature: 24 oC +/- 4 Humidity: RH of 55% +/- 10 | |||||||

| Speed(In Sq.Meter/Hr) |

Print DPI

|

Passes

|

X4403

|

X8403

|

X4806

|

X8803

|

||

| Mode 1 |

488 x 300

|

1

|

457

|

251

|

–

|

457

|

||

| Mode 2 |

488 x 600

|

2

|

303

|

167

|

–

|

303

|

||

| Mode 3 |

488 x 900

|

3

|

221

|

122

|

–

|

221

|

||

| Mode 4 |

480 x 1200

|

4

|

165

|

91

|

–

|

165

|

||

| Mode 5 |

488 x 600

|

1

|

–

|

450

|

–

|

–

|

||

| Mode 6 |

488 x 1200

|

2

|

–

|

300

|

–

|

–

|

||

| Mode 7 |

488×1800

|

3

|

–

|

218

|

–

|

–

|

||

APPLICATIONS

SubliXpress Plus is the go-to sublimation printing machine for a variety of applications. This polyester fabric printing machine also prints on most other types of fabrics. Apart from being used as a sports apparel printing machine, this sublimation paper transfer machine is also used for various other applications like, fashion apparels, home furnishings, personalised merchandise, sports gear, etc.

Reviews

There are no reviews yet.